Plasma Cutting Services

At MAGAFİ Makine Enerji A.Ş., we support our expertise in metal processing with our high-tech plasma cutting services. With advanced equipment and an experienced team, we provide fast, precise, and cost-effective solutions to meet the cutting needs of various industries.

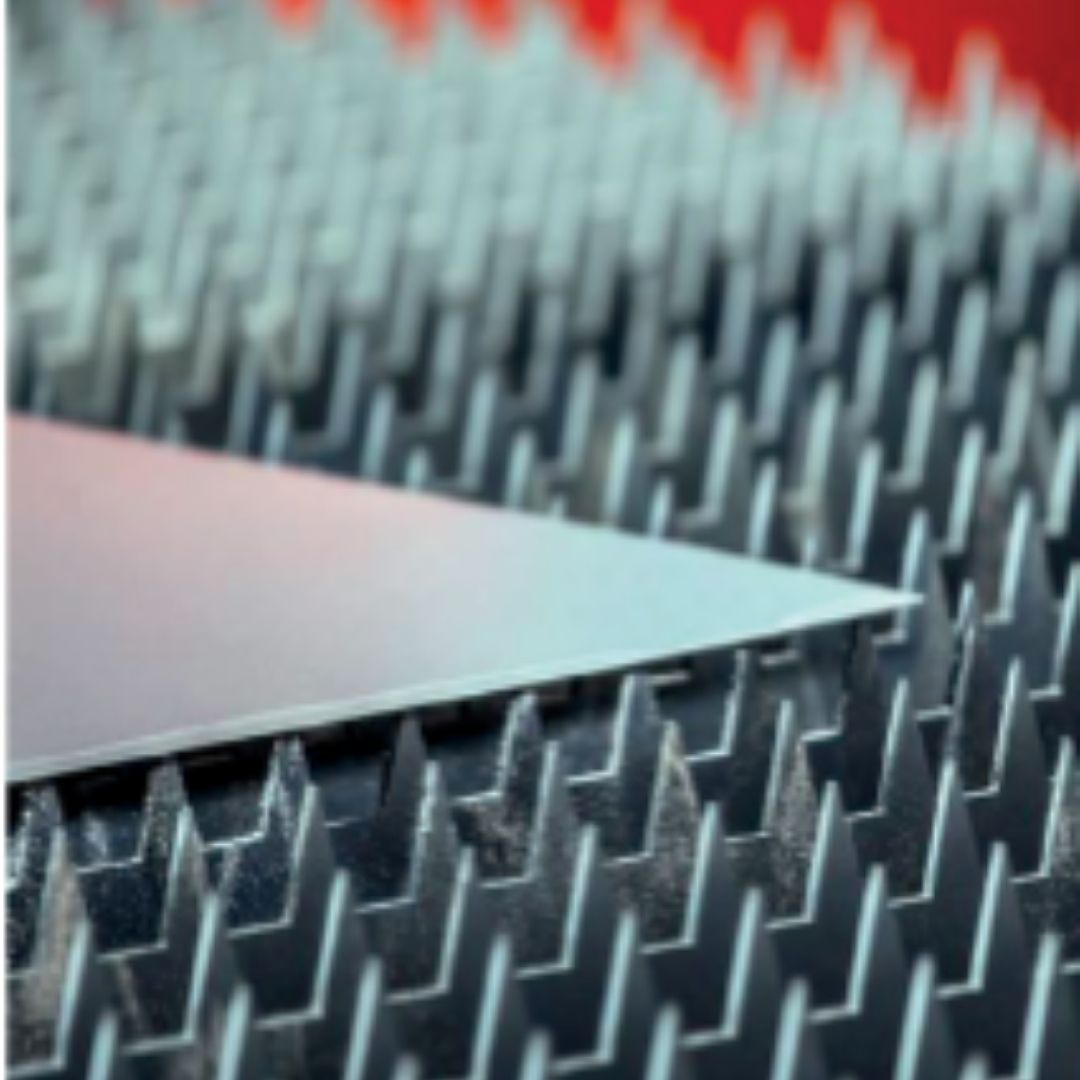

Plasma cutting machines are advanced technology devices that offer high speed, precision, and efficiency in the metalworking industry. These machines work by melting metal with a high-temperature electrical arc and can cut a wide variety of materials.

Our plasma cutting machines operate with electrical arc technology, melting metal at high temperatures to achieve precise cuts. This method delivers effective results on various metals, including iron, aluminum, stainless steel, and copper.

With broad material compatibility, fast cutting capability, and smooth surface finish, we optimize your production processes. With MAGAFİ assurance, we deliver your projects flawlessly and on time.

Plasma cutting machines are used in a wide range of applications, from industrial manufacturing to artistic designs, and offer significant advantages by increasing efficiency in the industry.

Industrial Machinery Expert

Our Quality CertificatesAt MAGAFİ Makina, our goal is to be your reliable partner for all guillotine shear cutting and metal forming projects. Our aim is to help you complete your projects in the best possible way with a focus on detail and flawless craftsmanship.

Advantages of Plasma Cutting Services

Plasma cutting stands out in metal processing with its high speed, flexibility, and superior cutting precision. The advantages we offer:

- 🔹 High Speed: Ideal for fast production processes.

- 🔹 Low Cost: Provides low operational costs with energy efficiency.

- 🔹 High Precision: Offers superior accuracy for detailed cuts.

- 🔹 Flexibility: Effective performance on various materials like iron, aluminum, stainless steel.

Applications of Plasma Cutting

Plasma cutting technology is preferred in many industries due to its high precision and speed advantages. Main application areas:

- 🔹 Construction and Infrastructure Projects

- 🔹 Automotive and Defense Industry

- 🔹 Shipbuilding and Energy Sector

- 🔹 Manufacturing and Machinery Industry

- 🔹 Metal Art and Design

Our CNC Plasma Cutting Machinery

We offer fast and precise cutting services on various metal types with our high-tech CNC plasma cutting machines.

- CNC Plasma Cutting Machine

- 🔹 Operating Dimensions: 3000 x 6000 mm

- 🔹 Maximum Power: 130 / 260 A

- 🔹 Cutting Capacity: 1 mm – 40 mm

- 🔹 Additional Feature: Marking in precision plasma

- OXY-FUEL CNC Plasma Cutting Machine

- 🔹 Operating Dimensions: 3000 x 12000 mm

- 🔹 Maximum Power: 130 / 260 A

- 🔹 Cutting Thickness: Up to 200 mm

- 🔹 Additional Feature: Bevel cutting with manual angle cutting head