Laser Cutting Services

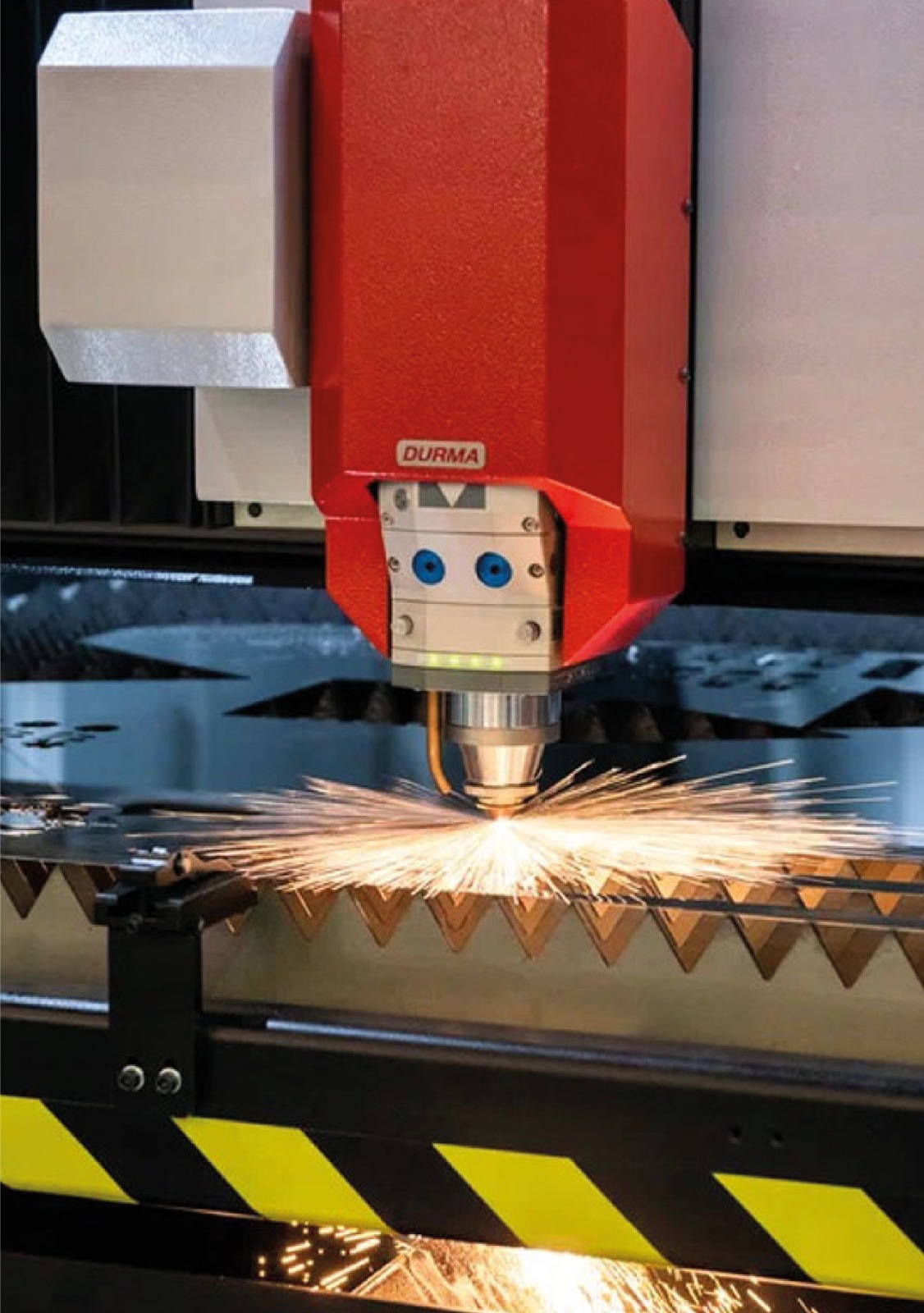

Laser cutting is a modern manufacturing technology used to shape metals and alloys with high precision.

Laser cutting technology is a manufacturing method that processes sheet metal, stainless steel, aluminum, and other metals with high precision to provide flawless cuts. Its speed, flexibility, and minimal error margin enhance efficiency in industrial production processes and reduce costs.

This method, performed with CNC-controlled machines, allows for fast and economical cuts with minimal error. It can be applied to various materials such as stainless steel, aluminum, copper, and brass.

Especially used in metal cutting processes, laser cutting offers many advantages over traditional methods, such as speed, accuracy, and flexibility. At MAGAFİ, we provide solutions that meet industry expectations with our extensive and modern laser cutting facilities.

Industrial Machinery Expert

Our Quality CertificatesOur company has the capability to produce even parts with complex geometries with high cutting quality using advanced CNC-controlled laser cutting systems. With automatic material feeding and optimization software, we ensure minimal material loss and maximum efficiency in our processes.

Advantages of Laser Cutting

Many types of metals such as steel, stainless steel, aluminum, brass, and copper can be processed quickly and flawlessly with laser cutting. Key advantages include:

- 🔹 Micron-level precision and excellent surface quality

- 🔹 Minimal deformation risk with contactless cutting method

- 🔹 Fast production process and low-cost advantage

- 🔹 Wide cutting capacity suitable for different thicknesses and materials

- 🔹 Flexibility suitable for custom designs and mass production demands

With minimal material waste and low energy consumption, laser cutting reduces environmental impact. Reliable results are obtained in a wide range of metal types, from steel to aluminum, brass to copper.

Experience the Difference in Laser Cutting with Magafi

MAGAFİ's laser cutting facilities have the capacity to handle the most challenging projects. With the speed, accuracy, and cost-effectiveness provided by fiber laser technology, you can complete your projects with quality and reliability. Contact us immediately for your product and service requests or visit our website for details.

Our Machinery Park

MAGAFİ's laser cutting services offer a wide range of solutions thanks to our machinery park suitable for various sizes and types of materials. Our modern equipment is equipped with high-power fiber laser technology, ensuring superior performance even in the most complex projects.

- 2500 x 6000 mm – 30 KW Fiber Laser

- ST37 (Steel/Black Sheet): Max 90 mm

- Stainless Steel: Max 60 mm

- Aluminum: Max 60 mm

- Copper: Max 20 mm

- Brass: Max 40 mm

- 2500 x 12000 mm – 30 KW Fiber Laser

- ST37 (Steel/Black Sheet): Max 90 mm

- Stainless Steel: Max 60 mm

- Aluminum: Max 60 mm

- Copper: Max 20 mm

- Brass: Max 40 mm

- 2500 x 8000 mm – 15 KW Fiber Laser

- Steel/Black Sheet: Max 50 mm

- Stainless Steel: Max 50 mm

- Aluminum: Max 30 mm

- 2000 x 4000 mm – 6 KW Fiber Laser

- Steel/Black Sheet: Max 25 mm

- Stainless Steel: Max 20 mm

- Aluminum: Max 15 mm

Our machinery park, equipped with modern technology, provides high-precision and high-quality laser cutting solutions. Thanks to our machines that offer high-efficiency production, we successfully execute even the most complex projects.